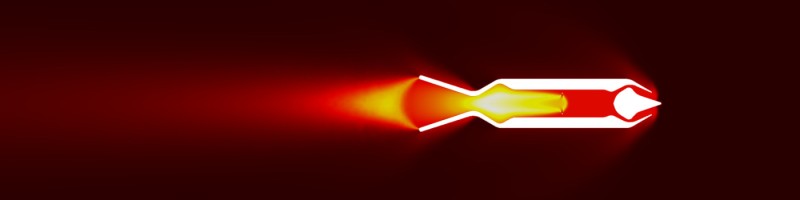

Noise Reduction Using Chevron Nozzles in Jet Engines, ANSYS Fluent In this project, noise generation from two types of nozzles (a regular one and a chevron nozzle) is simulated and analyzed using ANSYS Fluent software. Aeroacoustics is a branch of fluid dynamics dealing with the theory of noise generation in flows. Aeroacoustics phenomena are responsible for noise generation from aircraft engines, jet flows, drone propellers, etc. Chevron nozzles are a type of nozzle design used on jet engines, particularly on the engine’s exhaust system. They are characterized by their sawtooth pattern on the trailing edges of the nozzle. This pattern helps to mix the exhaust gases more efficiently with the ambient air. Chevron nozzles break up the high-speed exhaust jets into smaller, more manageable segments. This helps in reducing the noise generated due to the shearing effect when the high-speed jet exhaust mixes with the slower-moving ambient air. The improved mixing facilitated by chevron nozzles leads to a quieter operation, which is particularly beneficial for aircraft operating near urban areas. The geometry is designed in SpaceClaim and is meshed using ANSYS Meshing. The area around the nozzle is meshed unstructurally, while the rest of the domain is meshed structurally. The element number equals 989,310 for the chevron nozzle and 1,317,762 for the regular nozzle. https://lnkd.in/dPqw_fCb

Reza Amini’s Post

More Relevant Posts

-

Noise Reduction Using Chevron Nozzles in Jet Engines, ANSYS Fluent In this project, noise generation from two types of nozzles (a regular one and a chevron nozzle) is simulated and analyzed using ANSYS Fluent software. Aeroacoustics is a branch of fluid dynamics dealing with the theory of noise generation in flows. Aeroacoustics phenomena are responsible for noise generation from aircraft engines, jet flows, drone propellers, etc. Chevron nozzles are a type of nozzle design used on jet engines, particularly on the engine’s exhaust system. They are characterized by their sawtooth pattern on the trailing edges of the nozzle. This pattern helps to mix the exhaust gases more efficiently with the ambient air. Chevron nozzles break up the high-speed exhaust jets into smaller, more manageable segments. This helps in reducing the noise generated due to the shearing effect when the high-speed jet exhaust mixes with the slower-moving ambient air. The improved mixing facilitated by chevron nozzles leads to a quieter operation, which is particularly beneficial for aircraft operating near urban areas. The geometry is designed in SpaceClaim and is meshed using ANSYS Meshing. The area around the nozzle is meshed unstructurally, while the rest of the domain is meshed structurally. The element number equals 989,310 for the chevron nozzle and 1,317,762 for the regular nozzle. https://lnkd.in/djTVYHiu

Noise Reduction Using Chevron Nozzles in Jet Engines, ANSYS Fluent

https://www.mr-cfd.com

To view or add a comment, sign in

-

Turgo Turbine, ANSYS Fluent CFD Simulation Training The present problem simulates the water flow inside a Turgo water turbine by ANSYS Fluent software. The geometry is designed using Design Modeler software. The meshing of the model has been done using ANSYS Meshing software and the element number is 4,344,106. Mesh Motion (Sliding Mesh) is used to define the rotation of the blades inside the chamber. https://lnkd.in/d4Je4WSR

Turgo Turbine, ANSYS Fluent CFD Simulation Training

mr-cfd.com

To view or add a comment, sign in

-

Pool Boiling of Water around Horizontal Tube, CFD Simulation, ANSYS Fluent The problem numerically simulates a Pool Boiling unsteadily using ANSYS Fluent software. We design the model in Spaceclaim and then meshed it with ANSYS Meshing software generating 92,151 cells. The multi-phase Eulerian method is used for simulating the liquid phase of water and the vapor phase of bubbles The k-ɛ realizable model is performed to simulate turbulent behavior of the bubble. https://lnkd.in/dMNmPywi

Pool Boiling of Water around Horizontal Tube, CFD Simulation, ANSYS Fluent

https://www.mr-cfd.com

To view or add a comment, sign in

-

Solid Fuel Ramjet Engine, SFRJ, CFD Simulation, ANSYS Fluent In this project, a solid fuel ramjet (SFRJ) engine has been numerically simulated by ANSYS Fluent software. We design the 2-D model by the Design Modeler software. We Mesh the model with ANSYS Meshing software. The mesh type is Structured, and the element number equals 35,224. We use the Species Transport model to define the combustion process. https://lnkd.in/djAFM4SS

Solid Fuel Ramjet Engine, SFRJ, CFD Simulation, ANSYS Fluent

https://www.mr-cfd.com

To view or add a comment, sign in

-

Sludge Flow In Centrifugal Pump CFD Simulation The problem numerically simulates Slurry Flow in Centrifugal Pump using ANSYS Fluent software. We design the 3-D model with the Design Modeler software. We Mesh the model with ANSYS Meshing software, and the polyhedra element number equals 1,498,132. We use the Frame Motion to define the rotational movement in the rotating zone. The Mixture multiphase model is activated to model the effect of solid particles. https://lnkd.in/d4d3jWrR

Sludge Flow In Centrifugal Pump CFD Simulation

mr-cfd.com

To view or add a comment, sign in

-

Bulb Turbine, Sand erosion study CFD Simulation The current CFD Analysis models the Bulb Turbine via ANSYS Fluent software. We have designed the geometry using ANSYS Design Modeler software and generated the mesh on this geometry using ANSYS Meshing software. The Frame Motion technique is utilized to model the rotation of the turbine. The Discrete Phase Model (DPM) account for the presence of sand particles. The Erosion on the turbine, due to particle collision is investigated. https://lnkd.in/dEr-QnJ7

Bulb Turbine, Sand erosion study CFD Simulation

https://www.mr-cfd.com

To view or add a comment, sign in