HAND CRIMP TOOL SPECIFICATION SHEET - Molex

HAND CRIMP TOOL SPECIFICATION SHEET - Molex

HAND CRIMP TOOL SPECIFICATION SHEET - Molex

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

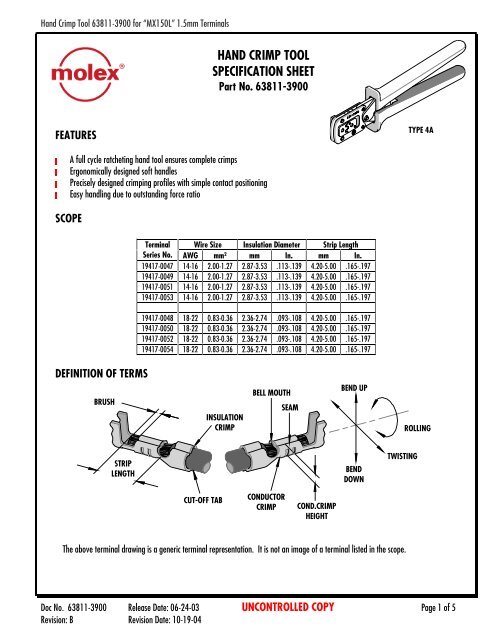

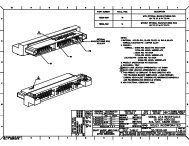

Hand Crimp Tool 63811-3900 for “MX150L” 1.5mm Terminals<br />

FEATURES<br />

BRUSH<br />

STRIP<br />

LENGTH<br />

CUT-OFF TAB<br />

<strong>HAND</strong> <strong>CRIMP</strong> <strong>TOOL</strong><br />

<strong>SPECIFICATION</strong> <strong>SHEET</strong><br />

Part No. 63811-3900<br />

�� A full cycle ratcheting hand tool ensures complete crimps<br />

�� Ergonomically designed soft handles<br />

�� Precisely designed crimping profiles with simple contact positioning<br />

�� Easy handling due to outstanding force ratio<br />

SCOPE<br />

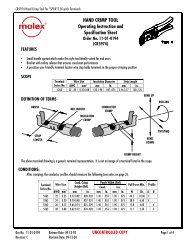

DEFINITION OF TERMS<br />

Terminal Wire Size Insulation Diameter Strip Length<br />

Series No. AWG mm² mm In. mm In.<br />

19417-0047 14-16 2.00-1.27 2.87-3.53 .113-.139 4.20-5.00 .165-.197<br />

19417-0049 14-16 2.00-1.27 2.87-3.53 .113-.139 4.20-5.00 .165-.197<br />

19417-0051 14-16 2.00-1.27 2.87-3.53 .113-.139 4.20-5.00 .165-.197<br />

19417-0053 14-16 2.00-1.27 2.87-3.53 .113-.139 4.20-5.00 .165-.197<br />

19417-0048 18-22 0.83-0.36 2.36-2.74 .093-.108 4.20-5.00 .165-.197<br />

19417-0050 18-22 0.83-0.36 2.36-2.74 .093-.108 4.20-5.00 .165-.197<br />

19417-0052 18-22 0.83-0.36 2.36-2.74 .093-.108 4.20-5.00 .165-.197<br />

19417-0054 18-22 0.83-0.36 2.36-2.74 .093-.108 4.20-5.00 .165-.197<br />

INSULATION<br />

<strong>CRIMP</strong><br />

BELL MOUTH<br />

CONDUCTOR<br />

<strong>CRIMP</strong><br />

COND.<strong>CRIMP</strong><br />

HEIGHT<br />

BEND UP<br />

BEND<br />

DOWN<br />

TWISTING<br />

The above terminal drawing is a generic terminal representation. It is not an image of a terminal listed in the scope.<br />

ROLLING<br />

Doc No. 63811-3900 Release Date: 06-24-03 UNCONTROLLED COPY Page 1 of 5<br />

Revision: B Revision Date: 10-19-04<br />

SEAM<br />

TYPE 4A

Hand Crimp Tool 63811-3900 for “MX150L” 1.5mm Terminals<br />

CONDITIONS:<br />

After crimping, the crimp profiles should measure the following (see notes on page 4).<br />

Terminal Bell mouth Conductor Brush Bend up Bend Down Twist Roll<br />

Series No. mm In. mm In. Degree Degree<br />

19417-0047 0.25-1.25 .010-.049 0.15-0.65 .006-.026 5 5 4 8<br />

19417-0049 0.25-1.25 .010-.049 0.15-0.65 .006-.026 5 5 4 8<br />

19417-0051 0.25-1.25 .010-.049 0.15-0.65 .006-.026 5 5 4 8<br />

19417-0053 0.25-1.25 .010-.049 0.15-0.65 .006-.026 5 5 4 8<br />

19417-0048 0.25-1.25 .010-.049 0.15-0.65 .006-.026 5 5 4 8<br />

19417-0050 0.25-1.25 .010-.049 0.15-0.65 .006-.026 5 5 4 8<br />

19417-0052 0.25-1.25 .010-.049 0.15-0.65 .006-.026 5 5 4 8<br />

19417-0054 0.25-1.25 .010-.049 0.15-0.65 .006-.026 5 5 4 8<br />

Terminal Wire Size<br />

Series No. 2<br />

AWG mm<br />

Cond. Crimp<br />

Height<br />

mm In.<br />

Cond. Crimp<br />

Width<br />

mm In.<br />

Insul. Crimp<br />

Height REF<br />

mm In.<br />

Insul. Crimp<br />

Width<br />

mm In.<br />

Profile<br />

Pull Force Min.<br />

AWG<br />

N Lb. 18-22 14-16<br />

19417-0047 14 2.00 1.70 REF .067 REF 2.60 REF .102 REF 3.50 max. .138 max. 4.30 REF .169 REF 222.6 50.00 X<br />

19417-0047 16 1.27 1.70 REF .067 REF 2.60 REF .102 REF 3.50 max. .138 max. 4.30 REF .169 REF 133.5 30.00 X<br />

19417-0049 14 2.00 1.70 REF .067 REF 2.60 REF .102 REF 3.50 max. .138 max. 4.30 REF .169 REF 222.6 50.00 X<br />

19417-0049 16 1.27 1.70 REF .067 REF 2.60 REF .102 REF 3.50 max. .138 max. 4.30 REF .169 REF 133.5 30.00 X<br />

19417-0051 14 2.00 1.70 REF .067 REF 2.60 REF .102 REF 3.50 max. .138 max. 4.30 REF .169 REF 222.6 50.00 X<br />

19417-0051 16 1.27 1.70 REF .067 REF 2.60 REF .102 REF 3.50 max. .138 max. 4.30 REF .169 REF 133.5 30.00 X<br />

19417-0053 14 2.00 1.70 REF .067 REF 2.60 REF .102 REF 3.50 max. .138 max. 4.30 REF .169 REF 222.6 50.00 X<br />

19417-0053 16 1.27 1.70 REF .067 REF 2.60 REF .102 REF 3.50 max. .138 max. 4.30 REF .169 REF 133.5 30.00 X<br />

19417-0048 18 0.83 1.20 REF .047 REF 2.10 REF .083 REF 3.00 max. .118 max. 3.40 REF .134 REF 89.0 20.00 X<br />

19417-0048 20 0.58 1.20 REF .047 REF 2.10 REF .083 REF 3.00 max. .118 max. 3.40 REF .134 REF 57.9 13.00 X<br />

19417-0048 22 0.36 1.20 REF .047 REF 2.10 REF .083 REF 3.00 max. .118 max. 3.40 REF .134 REF 35.6 8.00 X<br />

19417-0050 18 0.83 1.20 REF .047 REF 2.10 REF .083 REF 3.00 max. .118 max. 3.40 REF .134 REF 89.0 20.00 X<br />

19417-0050 20 0.58 1.20 REF .047 REF 2.10 REF .083 REF 3.00 max. .118 max. 3.40 REF .134 REF 57.9 13.00 X<br />

19417-0050 22 0.36 1.20 REF .047 REF 2.10 REF .083 REF 3.00 max. .118 max. 3.40 REF .134 REF 35.6 8.00 X<br />

19417-0052 18 0.83 1.20 REF .047 REF 2.10 REF .083 REF 3.00 max. .118 max. 3.40 REF .134 REF 89.0 20.00 X<br />

19417-0052 20 0.58 1.20 REF .047 REF 2.10 REF .083 REF 3.00 max. .118 max. 3.40 REF .134 REF 57.9 13.00 X<br />

19417-0052 22 0.36 1.20 REF .047 REF 2.10 REF .083 REF 3.00 max. .118 max. 3.40 REF .134 REF 35.6 8.00 X<br />

19417-0054 18 0.83 1.20 REF .047 REF 2.10 REF .083 REF 3.00 max. .118 max. 3.40 REF .134 REF 89.0 20.00 X<br />

19417-0054 20 0.58 1.20 REF .047 REF 2.10 REF .083 REF 3.00 max. .118 max. 3.40 REF .134 REF 57.9 13.00 X<br />

19417-0054 22 0.36 1.20 REF .047 REF 2.10 REF .083 REF 3.00 max. .118 max. 3.40 REF .134 REF 35.6 8.00 X<br />

Doc No. 63811-3900 Release Date: 06-24-03 UNCONTROLLED COPY Page 2 of 5<br />

Revision: B Revision Date: 10-19-04

Hand Crimp Tool 63811-3900 for “MX150L” 1.5mm Terminals<br />

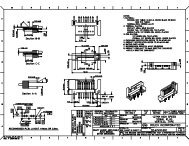

OPERATION<br />

Open the tool by squeezing the handles together, at the end of the closing stroke, the ratchet mechanism will release the handles,<br />

and the hand tool will spring open.<br />

Crimping Terminals<br />

1. Lift the wire stop blade up.<br />

2. Insert the terminal fully into the correct die profile and the<br />

locator slot until the terminal is fully seated and stops.<br />

3. Bring down the wire stop blade. Make sure the wire stop blade is<br />

fully seated on the terminal behind the conductor grip section.<br />

4. Slide the pre-stripped wire into the terminal; make sure to aim<br />

the wire brush towards the tip point on the wire stop blade (See<br />

Figure 1). Align the wire so that it is parallel and sitting into the<br />

terminal. Maintain a light and constant pressure on the wire that<br />

is seated in the terminal at all times. (Do not let go of the wire.)<br />

Be sure to hold the wire and terminal in place until the terminal<br />

is fully crimped. (See Figure 2).<br />

5. Close the tool until the ratchet releases.<br />

6. Lift the wire stop blade up.<br />

7. Carefully remove the crimped terminal.<br />

WIRE STOP<br />

BLADE<br />

LOCATOR<br />

TERMINAL<br />

RETAINER<br />

CONDUCTOR<br />

ANVIL<br />

SPACER<br />

Figure 2<br />

CONDUCTOR<br />

PUNCH<br />

INSULATION<br />

PUNCH<br />

WIRE<br />

INSULATION<br />

ANVIL<br />

LOCATOR<br />

TERMINAL<br />

Figure 1<br />

Note: To maintain a good brush control and a<br />

consistent bell mouth the crimping instructions must be<br />

followed.<br />

WIRE STOP<br />

BLADE<br />

PRE-STRIPPED<br />

WIRE<br />

Doc No. 63811-3900 Release Date: 06-24-03 UNCONTROLLED COPY Page 3 of 5<br />

Revision: B Revision Date: 10-19-04

Hand Crimp Tool 63811-3900 for “MX150L” 1.5mm Terminals<br />

Maintenance<br />

It is recommended that each operator of the tool be made aware of, and responsible for, the following maintenance steps:<br />

1. Remove dust, moisture, and other contaminants with a clean brush, or soft, lint free cloth.<br />

2. Do not use any abrasive materials that could damage the tool.<br />

3. Make certain all pins; pivot points and bearing surfaces are protected with a thin coat of high quality machine oil. Do not oil<br />

excessively.<br />

4. When tool is not in use, keep the handles closed to prevent objects from becoming lodged in the crimping dies, and store the<br />

tool in a clean, dry area.<br />

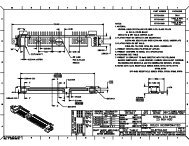

Miscrimps or Jams (See Figure 3)<br />

Should this tool ever become stuck or jammed in a partially closed position, Do Not force the handles open or closed. The tool<br />

will open easily by pushing the ratchet release lever.<br />

Warranty<br />

This tool is for electrical terminal crimping purposes only. This tool is made of the best quality materials. All vital components are long<br />

life tested. All tools are warranted to be free of manufacturing defects for a period of 30 days. Should such a defect occur, we<br />

would exchange the tool free of charge. This will not be applicable to altered, misused, or damaged tools. This tool is designed for<br />

hand use only. Any clamping, fixturing, or use of handle extensions voids this warranty.<br />

Hand held crimping tools are intended for low volume, prototyping, or repair requirements only.<br />

Notes:<br />

Caution: Repetitive use of this tool should be avoided.<br />

1. This tool should only be used for the terminals and wire gauges specified on this sheet.<br />

2. This tool is not adjustable. Variations in tools, terminals, wire stranding and insulation types may affect crimp height.<br />

3. This tool is intended for standard conductor sizes. It may not give a good insulation crimp support for all insulation sizes.<br />

4. <strong>Molex</strong> does not repair hand tools (see warranty above) The replacement parts listed are the only parts available for repair. If the<br />

handles or crimp tooling is damaged or worn, a new tool must be purchased.<br />

5. Pull force should be used as the final criteria for an acceptable crimp. Pull force is measured with no influence from the insulation<br />

crimp. The insulation should be stripped long (1/2 in.) so the insulation grips on the terminal do not grip the wire insulation or<br />

the conductor. Refer to <strong>Molex</strong> Quality Crimping Handbook 63800-0029 for additional information on crimping and crimp testing.<br />

6. <strong>Molex</strong> does not certify crimp hand tools.<br />

CAUTION: <strong>Molex</strong> crimp specifications are valid only when used with <strong>Molex</strong> terminals, applicators and tooling.<br />

Doc No. 63811-3900 Release Date: 06-24-03 UNCONTROLLED COPY Page 4 of 5<br />

Revision: B Revision Date: 10-19-04

Hand Crimp Tool 63811-3900 for “MX150L” 1.5mm Terminals<br />

PARTS LIST<br />

M4 X 12mm<br />

LONG BHCS<br />

2<br />

LOCATOR<br />

Item Number Order Number Description Quantity<br />

1 63600-0520 Crimping Spring 2<br />

2 63811-3975 Locator 1<br />

3 63600-0525 Handle Spring 1<br />

1<br />

Figure 3<br />

<strong>CRIMP</strong>ING<br />

SPRING (2)<br />

<strong>Molex</strong> Application Tooling Group<br />

1150 E. Diehl Road<br />

Naperville, IL, 60563<br />

Tel: 630-969-4550<br />

Fax: 630-505-0049<br />

Visit our Web site at http://www.molex.com<br />

RATCHET<br />

RELEASE LEVER<br />

<strong>HAND</strong>LE<br />

SPRING<br />

Doc No. 63811-3900 Release Date: 06-24-03 UNCONTROLLED COPY Page 5 of 5<br />

Revision: B Revision Date: 10-19-04<br />

3